Using Your Docking Panel

The Docking Panel provides a mechanical and electronic platform for the PDQ Board and additional Wildcards. It hosts a high-efficiency 1 amp 5 volt modular switching power supply, dual DB-9 serial connectors, dual DB-25 IO connectors, a power jack, and a master power switch. The serial connectors, IO connectors, jack and switch are designed for easy mounting to an instrument panel. This chapter will familiarize you with the Docking Panel hardware and its functions. In particular, you’ll learn:

- The locations and pinouts of the Docking Panel’s connectors and header; and,

- How to connect your PDQ Board to your Docking Panel.

A tour of the hardware

The Docking Panel mounts directly to the PDQ Board. The PDQ Board is a C-language single board computer (SBC) based on the Freescale 9S12 (HCS12) microcontroller; it is ideal for instrumentation and control applications.

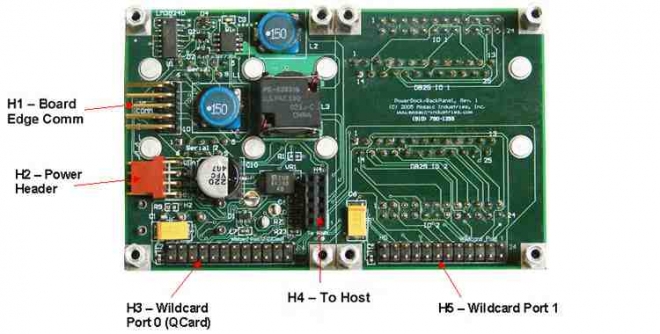

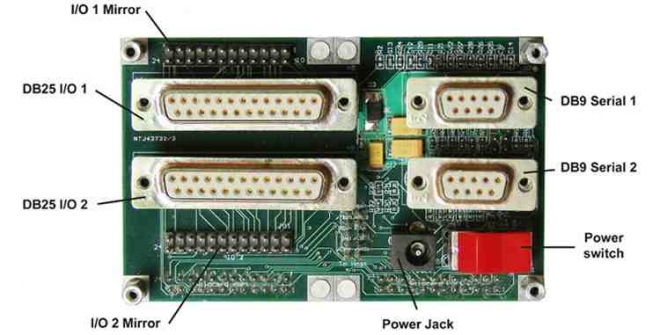

Figure 2-1 and Figure 2-2 show both sides of the Docking Panel, which has the same width and length as the PDQ Board. All of the connectors and headers are described in the following sections.

The Docking Panel’s front side

Looking at the front side of the Docking Panel board, you can see that it provides two Wildcard module headers. You can directly plug PDQ Board into the mating Wildcard Bus and Docking Panel/PDQ Comm headers (H3, H7 and H5 on the PDQ Board). Up to 8 Wildcards can then stack on top of the PDQ Board, up to 4 Wildcards on each of the two stacking go-through connectors.

The Docking Panel’s back side

The Docking Panel’s back side hosts serial connectors, IO connectiors, a power switch and a power jack. They are mounted so that the board can mount directly to an instrument panel if desired using ½ inch stand-offs. The instrument panel requires cutouts for the connectors, and holes for the power switch and power jack.

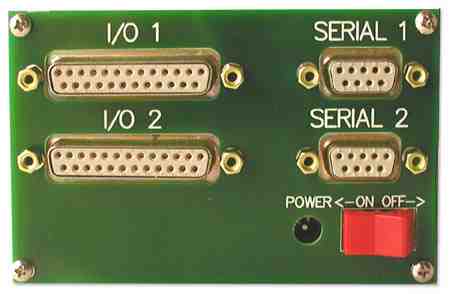

Optional cover plate

An optional cover plate simplifies enclosure mounting and provides a clean solid appearance.

Power

The Docking Panel takes an unregulated 8 to 26 volts from the power jack shown in Figure 2-2 or through the power header (H2) shown in Figure 2-1 and passes it though an EMI filter and surge protection circuitry to provide a clean V+Raw supply (for any Wildcards that might need it). The V+Raw is then regulated using a very clean, high-efficiency switching regulator to create a 5 volt power source. The switching regulator using a following low pass LC filter to assure that switching ripple is less than 5 mV peak-to-peak. The power source can supply up to 1 amp to power a PDQ Board and up to 8 Wildcards.

H2: Power header

The following table provides the power header’s pinout:

| Power Header | ||

|---|---|---|

| Pin | Signal | |

| 1 | – | VIN (8 to 26 Volts) |

| 2 | – | GND |

| 3 | – | +5 VDC |

| 4 | – | VBAT |

If a battery is installed on your PDQ Board (i.e. you ordered the Starter Kit or the PDQ Board with the Real time clock option), the VBAT signal allows you to monitor the state of the battery. If a battery is not installed, you can use this signal to externally battery backup your real-time clock by supplying 3 to 4.5 volts when your system is off.

Communications connectors

The PDQ Board’s two serial ports are brought out to the two DB-9 connectors as shown in Figure 2-2 and the 10-pin right angle header as shown in Figure 2-1.

The Serial1 and Serial2 ports on the PDQ Board can be jumper configured for RS232 or RS485 communication. However, only the RS232 lines are brought out to the DB-9 Connectors. Surface mount resistor pads on the Docking Panel allow you to configure the signals going to the Serial1 DB-9 connector for RS485 operation. The Serial2 DB-9 connector supports only RS232; however, resistor pads on the Docking Panel also allow you to use the signals that implement the secondary serial port for RS232 hardware handshaking on the Serial1 port. Please see the schematic of the Docking Panel in the appendix for more information and contact Mosaic Industries for custom configurations.

Standard DB-9 serial connector configurations

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Standard DB-25 IO headers

These two DB-25 connectors are mirrored on headers H10 and H11. This allows you to easily route IO to the back panel of your instrument and make connection via a standard DB-25 cable. For instance, you could route the Analog IO Header (H4) and the Digital IO Header (H8) to these DB-25 connectors to access all of the PDQ Board's native IO.

H8 DB-25 Pins ⇔ H10 Mirror Pins

Pins 1 through 24 on DB-25 Connector 1 at header H8 are connected directly to pins 1 through 24 respectively on header H10. Pin 25 (GND) on DB-25 Connector 1 in not connected to H10.

H9 DB-25 Pins ⇔ H11 Mirror Pins

Pins 1 through 24 on DB-25 Connector 2 at header H9 are connected directly to pins 1 through 24 respectively on header H11. Pin 25 (GND) on DB-25 Connector 2 in not connected to H11.

Communications header

Both serial ports of the PDQ Board are brought out to the 10-pin board-edge communications header (H1) on the Docking Panel. The communications header on the PDQ Board differs slightly from the communications header on the Docking Panel. Pins 4 and 10 on the PDQ Board communications header are the Serial2 RS485 signals XCV2+ and XCV2-, respectively, while pins 10 and 4 on the Docking Panel bring out GND and +5V. Note that the PDQ Board and Docking Panel each have a 10-pin board-to-board mating Comm header; these should not be confused with the board-edge Comm headers being discussed here.

| Docking Panel Communications Header H1 | |||

|---|---|---|---|

| Signal | Pins | Signal | |

| /TxD1 | —1 | 2— | /RxD1 |

| GND | —3 | 4— | GND |

| RS485 XCVR- | —5 | 6— | RS485 XCVR+ |

| /TxD2 | —7 | 8— | /RxD2 |

| GND | —9 | 10— | +5V |

| Note that this pinout differs from that of the PDQ Board pinout. On the PDQ Board pin 4 is connected to XCV2+ and pin 10 is connected to XCV2-. | |||

Host header

The Docking Panel has a header to bring send communication lines to the PDQ Board. The QCard Controller is also compatible with this pinout.

| H4: To Host | |||

|---|---|---|---|

| Signal | Pins | Signal | |

| /TxD1 | —1 | 2— | /RxD1 |

| DGND | —3 | 4— | /MOD1_CS/NC |

| RS485 XCV1- | —5 | 6— | RS485 XCV1+ |

| /TxD2 | —7 | 8— | /RxD2 |

| DGND | —9 | 10— | VBAT |

Wildcard headers

The PDQ Board’s Wildcard Port0 Header (H3) allows you to mount up to four Wildcards simultaneously at module addresses 0 through 3. The Wildcard Port1 Header (H7) supports up to four additional Wildcards at module addresses 4 through 7. The 24-pin stackable go-through Wildcard connectors provide the following signals:

| Wildcard Port Header | |||

|---|---|---|---|

| Signal | Pins | Signal | |

| GND | —1 | 2— | +5V |

| /IRQ | —3 | 4— | V+RAW |

| SEL1/XMIT- | —5 | 6— | SEL0/XMIT+ |

| MOSI/XCV- | —7 | 8— | MISO/XCV+ |

| /RESET | —9 | 10— | SCK |

| /MOD.CS | —11 | 12— | 16MHz |

| E | —13 | 14— | R/W |

| /OE | —15 | 16— | /WE |

| AD7 | —17 | 18— | AD6 |

| AD5 | —19 | 20— | AD4 |

| AD3 | —21 | 22— | AD2 |

| AD1 | —23 | 24— | AD0 |

How to install your PDQ Board

If you ordered the PDQ Board Starter Kit, the PDQ Board and Docking Panel should have been shipped to you assembled together. However, if you purchased them separately, it is a snap to put them together. Simply align all the mounting holes of the two boards, and ensure that the dual 24-pin stacking go-through Wildcard module headers line up, and press the boards together.

See also → Installing and Connecting to PDQ Board